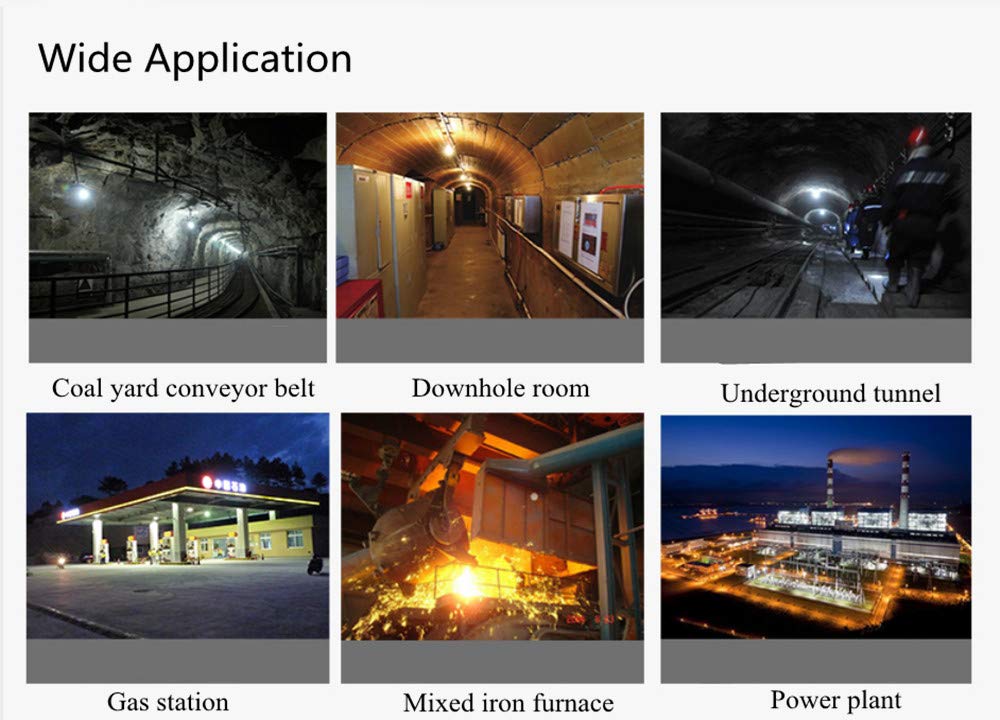

Compared with traditional explosion-proof lamps, they are smaller in size, lighter in weight, longer in life and more affordable in price. The selection of explosion-proof lamps has increased from 20% in 2013, 40% in 2014, and 70% in 2015. LED explosion-proof lights have become mainstream products in explosion-proof places.

Thanks to the promotion of petroleum and related industries, explosion-proof lights occupy a very important market position in mining, petroleum, military, transportation and other industrial fields. According to the "Engineering Lighting Explosion-proof Lamp Market" research report, the industrial lighting market will reach US$5.204 billion in 2022, of which the output value of LED explosion-proof lamps will reach US$248 million.

WHAT IS EXPLOSION PROOF LIGHT?

Explosion-proof lamps are special lighting appliances specially used in industrial operations. Explosion-proof lamps have high luminous efficiency, good light transmittance, and long service life. After high-tech means of sealing treatment, they are not only waterproof, dustproof, wear-resistant and anti-corrosion. It can be used in some wet or corrosive environments without any influence.

At the same time, the shell is sturdy, which is safer and more reliable during use. It is inseparable from its use in daily industrial operations almost every day. It can be seen that its utilization rate is quite high.

With the development of industrialization, the importance of explosion-proof lamps can be more reflected in petrochemical installations, oil platforms, gas stations, oil pump rooms, transfer stations and other flammable and explosive places.

“In this evaluation, in addition to the basic optical parameters of the luminaire, we have also carried out a comprehensive evaluation of this LED explosion-proof lamp from the aspects of shell structure, heat resistance, IP level requirements, shock resistance, thermal shock resistance, shell pressure resistance, and internal ignition. Orientation test to verify its explosion-proof performance.”

The test samples were from Fujian CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO ., Ltd the basic optical parameters were tested by Shenzhen Nanfang Lixun Testing Co., Ltd., and the explosion-proof performance experiment was tested by Guangzhou Special Electromechanical Equipment Testing Institute.

Next, let's take a look at this explosion-proof and maintenance-free LED lighting. In appearance, this lamp is more similar to a mining lamp, with a simple and firm appearance. The overall size is Φ350*210mm. The power supply of the product is installed by the method of filling the bare board with glue and sealing it in the power supply cavity. The advantage of this is to avoid the explosion caused by the spark between the circuits.

“This one-piece glass lens luminaire adopts a typical fixed luminaire design. It is connected to the outside through wiring terminals and has a crimping device. It is a Class I luminaire. The special feature is that the luminaire is connected very firmly. The whole product is moderate in weight and touchable. The product has a smooth feel, no sharp edges and corners, and meticulous workmanship.”

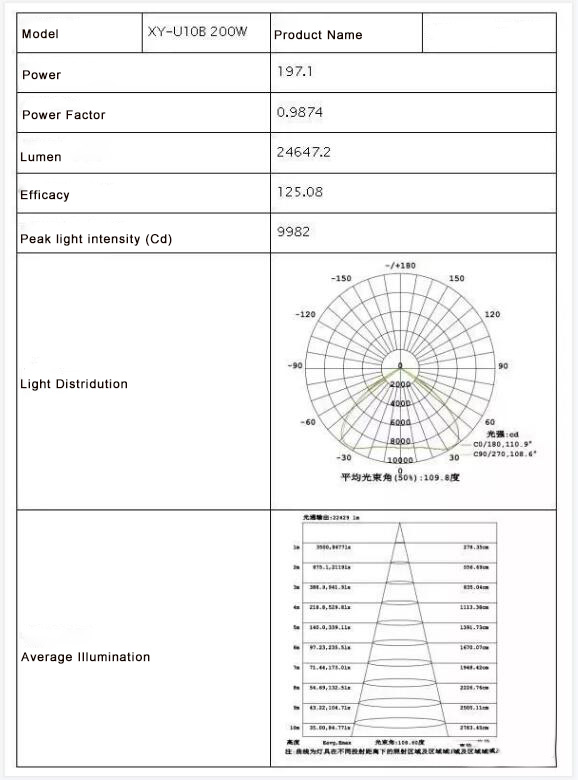

01.PHOTOELECTRIC PARAMETER

Judging from the data, the performance of this lamp is quite satisfactory. Now the general light efficiency of lamps and lanterns basically reaches 120Lm/w or more, and the performance of lamps and lanterns is not excellent at 125.08lm/w, but the light distribution is very good, close to the square light distribution, and the actual use It is more convenient for design and construction in the process, which can effectively provide the utilization rate of the working face and avoid the existence of dark areas and zebra crossings.

Let's take a look at the explosion-proof performance of this product.

This time, an explosion-proof test of Exd IIC T3Gb level is carried out, which belongs to explosion-proof products. The so-called explosion-proof type is an explosion-proof type of electrical equipment. Explosive mixtures explode internally without damage, and do not cause external ignition of an explosive atmosphere of one or more gases or neat forms.

The popular understanding is that it is on fire, and the shell can also isolate the inside from the outside, and will not cause an external explosion.

02. Explosion-proof structure inspection

The specific inspection results are as follows:

1. The content of the explosion-proof sign nameplate is complete, the warning sign information is clear, and the location of the sign is obvious;

2. The grounding meets the requirements, with a grounding mark;

3. With cable entry device, there are sealing measures.

The number/letter height of the nameplate is greater than 2mm, and the other signs are greater than 5mm. After the label wipe test, the handwriting is still clear, and all inspections meet the relevant requirements of the GB 3836.1-2010 standard.

03. Explosion-proof equipment structure inspection

1. Cylinder joint surface (connection cavity): L=12.64mm, i=0.08mm, Ra=6.3μm;

2. Cylinder joint surface (power cavity): L=13.66mm, i=0.12mm, Ra=6.3μm;

3. Threaded joint surface (introduction device compression nut): pitch 1.5mm, meshing depth 10.78mm, meshing buckle number 7;

- Bonding and bonding surface (glass lens): the volume of the inner cavity of the lens is less than 100cm3, the bonding width is 8.08mm, and there is a lens press cover.

Summary:

When designing the structure of flameproof lamps, many companies often focus on the shape and strength design of the flameproof shell but ignore the fasteners, introduction devices, transparent parts, suspension devices, signs, etc. that form an integral part of the shell. Design of other devices. This LED explosion-proof lamp is perfect and in place in the details of the joint surface.

04.Maximum Surface Temperature

The maximum surface temperature is related to the power of the lamp and the size of the housing, which directly affects the cost of the lamp. On the one hand, the temperature is too high, which affects the life of the lamp, and on the other hand, the temperature reaches the ignition point of dust or gas, which may easily cause dust or gas explosion.

The specific test results are as follows

Test Conditions:

The working temperature is measured under the rated conditions of the electrical equipment. The test to determine the maximum surface temperature should be between 90%-110% of the rated voltage of the electrical equipment (or 90%-110% of the rated current), and the most unfavorable point of the equipment reaching the maximum surface temperature The maximum surface temperature shall not exceed the temperature group or temperature of the explosion-proof mark.

1. Test voltage: 0.9 x 220VAC 50Hz, 220VAC 50Hz, 1.1 x 220VAC 50Hz;

2. The maximum working temperature of the sealing ring is 75.9°C, and the maximum surface temperature of the lamp (at the center of the glass lens) is 100.7°C.

Summary:

This lamp belongs to Class I lamps. According to the use environment, the maximum surface temperature does not exceed 150°C (with coal dust accumulation) and 450°C (without coal dust accumulation). From the test results alone, the maximum working temperature of the sealing ring is 75.9 ℃, the lens center temperature is 100.7 ℃, the performance is still very good.

05.Detonation test

Next, let's take a look at two key tests for flameproof explosion-proof lamps: protection level and internal ignition non-transmission test.

Enclosure rating

The test results meet the corresponding explosion-proof category IP66 test requirements of GB4208.

Internal ignition without detonation test

Each flameproof chamber is tested according to the corresponding electrical equipment type test requirements. After 5 times of internal ignition and no explosion test, no explosion should occur.

Summary:

The explosion-proof type adopts the principle of gap explosion-proof, that is, the use of metal gaps can prevent the spread of the explosion flame and cool the temperature of the explosion product, so as to achieve flame extinguishing and cooling, and suppress the expansion of the explosion. A structure designed on the principle of principle.

Taking measures is a type of explosion protection that allows internal explosions and prevents flame propagation, and is the most commonly used type of explosion protection.

Even if the explosive gas mixture enters the flameproof enclosure and is ignited, the flameproof enclosure can withstand the explosion pressure of the explosive gas mixture inside and prevent the internal explosion from propagating to the explosive mixture around the enclosure.

The protection level of this lamp is IP66. According to the joint test results, these two parameters fully reflect the explosion-proof performance of the product. The shell can isolate the inside from the outside without affecting each other.

06.Heat resistance test

The non-metallic shell and the non-metallic parts of the shell shall pass the heat resistance test in Clause 26.8 of GB 3836.1-2010, and the material shall have no obvious change.

1. Test parts: whole lamp;

2. Relative humidity: 95%, temperature: 95°C;

3.Cycle: 28 days;

07.Cold resistance test

The non-metallic shell and the non-metallic components of the shell should be kept at room temperature for 24 hours after the heat resistance test, and then kept at the lowest working temperature for 24 hours. There should be no significant change in the sample after the test.

1. Test parts: whole lamp;

2. Test temperature: -40°C;

3. Test time: 24h;

Test results: There is no obvious change in the sample.

08.Impact test

Non-plastic shell (except glass transparent parts): impact energy 7J, test temperature 20±5°C;

Glass transparent parts: impact energy 4J, test temperature 20±5°C. The explosion-proof type of electrical equipment shall not be invalidated after the shock.

1. Test parts: metal shell and glass lens;

2. Test temperature: 24.5°C;

3. Test height: 0.7m from the metal shell, 0.4m from the glass lens;

4. Impact energy: metal shell impact energy 7J, glass lens impact energy 4J;

Test results: no damage affecting the explosion-proof type was found.

09. Thermal shock test

Standard requirements: The glass transparent cover and observation window should be at the highest working temperature, and spray water with a nozzle with a temperature of (10±5) °C and a diameter of 1mm, without breaking.

The test temperature is 10.0 °C, and the spray water with a diameter of 1 mm is sprayed on the glass surface when it reaches thermal equilibrium at a working environment temperature of 40 °C, and the surface of the glass lens is not broken.

10. Cable entry clamping test

When the following tensile force is applied to the cable or mandrel: 20 times the diameter of the mandrel or cable (in mm, round); 6 times the circumference of the cable (in mm, non-circular), the force is applied for 6 h test, The ambient temperature is (20 ± 5) ℃, if the displacement of the mandrel or cable sample does not exceed 6h, the sealing ring, packing or clamping assembly is considered qualified.

1. Test mandrel: 10mm, 14mm;

2. Test tension: 10mm mandrel 200N, 14mm mandrel 280N;

3. Test time: 6h;

4. Test results: 10mm mandrel displacement 5.66mm, 14mm

The displacement of the mandrel is 5.32mm, and there is no damage, all of which are less than 6mm.

11.Seal test and mechanical strength test

The introduction device is kept under the specified pressure for at least 10s, and there should be no leakage traces, which meets the requirements of the sealing test; after the mechanical strength test, there is no damage that affects the explosion-proof type, which meets the mechanical strength requirements.

1. Test mandrel: 10mm, 14mm;

2. Test pressure: keep 3.0MPa hydraulic pressure for 10s;

3. Test results: There is no leakage in the sealing test, and no damage in the mechanical strength test.

12.Housing pressure test

Each explosion-proof chamber is tested according to the corresponding electrical equipment type test requirements. For small equipment, the reference pressure cannot be measured, and the static pressure test is used. For IIC category equipment, a pressure of 1MPa should be applied when the volume is less than 10cm3, and a pressure of 2MPa should be applied when the volume is greater than 10cm3; Press time at least 10s. The test results should be no damage, no leakage.

Class IIC equipment:

1. Test cavity: wiring cavity, power supply cavity, light source cavity; (the volume of each cavity is greater than 10cm3)

2. Test pressure: 2MPa;

3. Pressurization time: 12s;

4. Test results: There is no damage to each cavity and no leakage.

(The above test data is provided by Guangzhou Special Electromechanical Equipment Testing Institute)

WANT TO SEND INQUIRY?

Post time: Jan-13-2022