The core point of this article: LED lighting industry chain, LED lighting company distribution heat map, and LED packaging technology analysis., etc.

A panoramic review of the LED lighting industry chain: LED lighting has a wide range of downstream subdivided applications

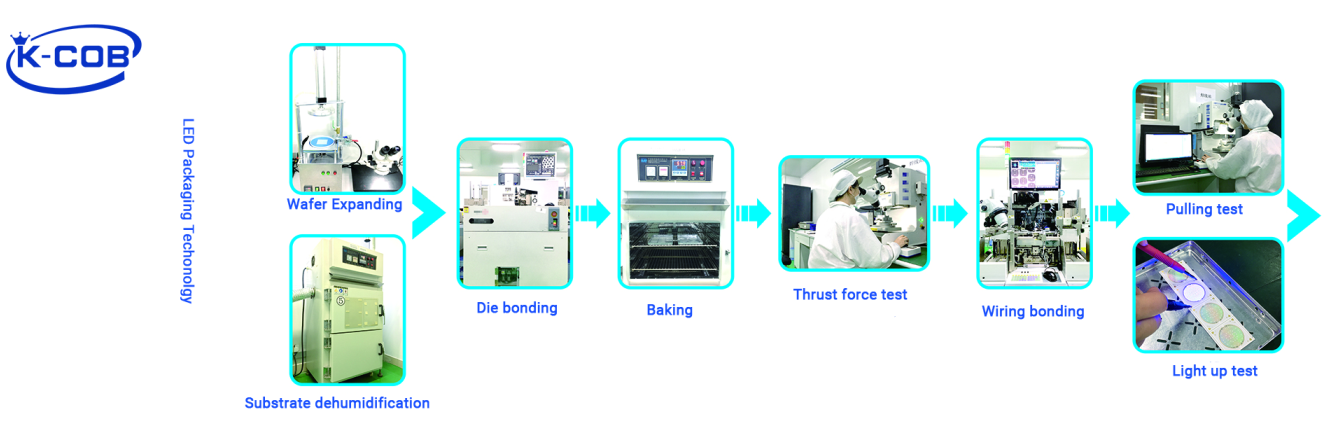

From the perspective of the LED lighting industry chain, the upstream includes suppliers of raw materials such as led wafers and LED chips; the midstream is mainly the LED lighting packaging process, including the processes of crystal expansion, crystal bonding, short baking, and wire bonding; the downstream lighting field can be roughly divided It is divided into two categories: general lighting and special lighting.

Among them, general lighting mainly includes home lighting, hotel lighting, etc., and special lighting mainly includes emergency lighting, automotive lighting, etc., with more applications.

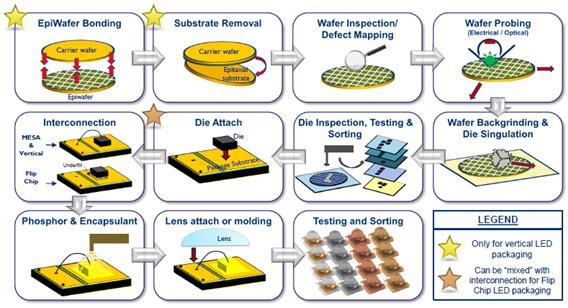

LED Packaging is an intermediate link necessary to realize the LED from the chip to the final product. The function of the package is to provide sufficient protection for the chip to prevent long-term exposure to the air or mechanical damage and failure to improve the stability of the chip; for LED packaging, it is also It is necessary to have good light extraction efficiency and good heat dissipation. A good package can make the LED have better luminous efficiency and heat dissipation environment, thereby improving the life of the LED.

The function of the package: to realize the function of inputting electrical signals, protecting the normal operation of the chip, and outputting visible light.

Most led lights manufacturers are belong to Downstream because it’s easy to produce and has low requirements for production technology.

As an important part in the LED industry chain, high power LED packaging is the core manufacturing technology that promotes the practical use of semiconductor lighting and display. Through the development of LED packaging and manufacturing technologies with low thermal resistance, high light efficiency, high reliability, good mechanical and electrical protection, high-performance LED lighting and display can be made, to promote the healthy development of the entire semiconductor lighting and display industry.

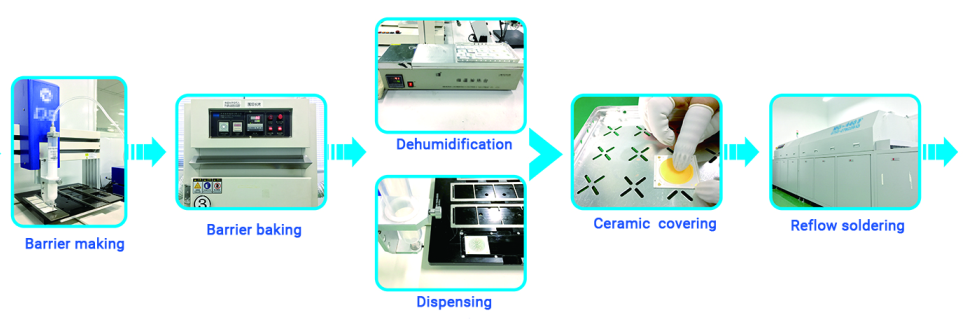

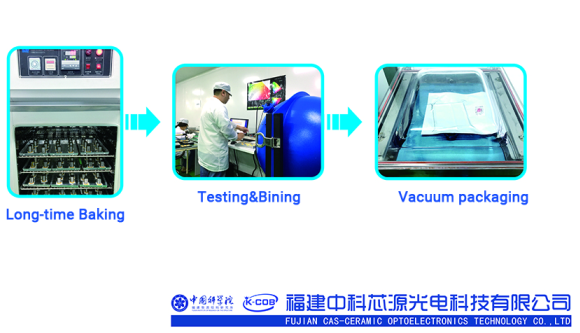

K-COB LED (Fujian CAS-Ceramic Optoelectronics Technology Co., Ltd.) is positioned in the middle reaches and downstream. Regarding the led packaging, their core packaging technology is: Phosphor ceramic cover+ solid packaging structure+ PCB board, dual heat-sink from both top and bottom. This feature brings better reliability and longer lifespan. They own the invention patent of phosphor ceramic cob led chip. By this technology, they can provide led sports lights, high bay lights, street lights, high mast lighting, and special lighting ( TV& film lighting, fishing marine lighting, and Military lighting).

The Ceramic never age and degradation. All KCOB series is LM-80 certificated.

Let’s see the process of ceramic cob led chips package production :

Chip On Board (COB) is a packaging technology that directly attach the LED chip to the PCB through glue or solder, and the electrical interconnection between chip and PCB is realized by wire bonding. The PCB can not only be low-cost FR-4 material (Glass fiber reinforced epoxy resin), but metal matrix or ceramic matrix composites with high thermal conductivity (such as aluminum substrates or copper clad ceramic substrates, etc.). Wire bonding can adopt hot ultrasonic bonding (gold wire ball welding) at high temperature and ultrasonic bonding at room temperature. COB technology is mainly used in LED packaging of high power multi-chip array. Compared with SMT, COB technology can not only greatly improves the power density of the package, but also reduces the thermal resistance of the package (generally 6-12W/mK).

For the cost and application, COB will become the mainstream direction of future luminaire design. COB packages multiple LED chips on the bottom plate to improve the brightness, and reduce the amount of input current of a single LED chip to ensure high efficiency. COB can greatly expand the heat dissipation area of the package, making the heat more easily transmitted to the housing. With the advantages of low thermal resistance, good light quality, solder-free and low cost, COB will be widely used in the future.

Thank you for your visit! Please feel free to contact us if you require high quality COB LED CHIPS & High power led Lights for your lighting projects. We will reply to you within 24 hours. Thank you for your time & message.

Post time: Dec-01-2021