What is COB light source? What are its advantages?

Cob light source has been a common product category in lighting products. There are many brands producing COB light source, but many people still do not understand what COB light source means. Today, Shelly will talk about this knowledge for you.

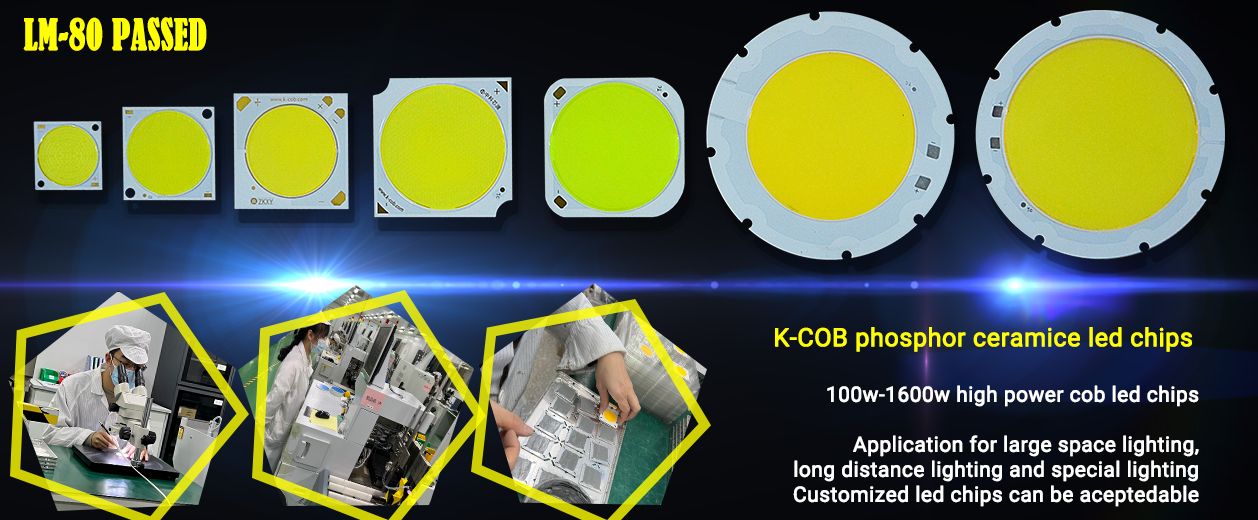

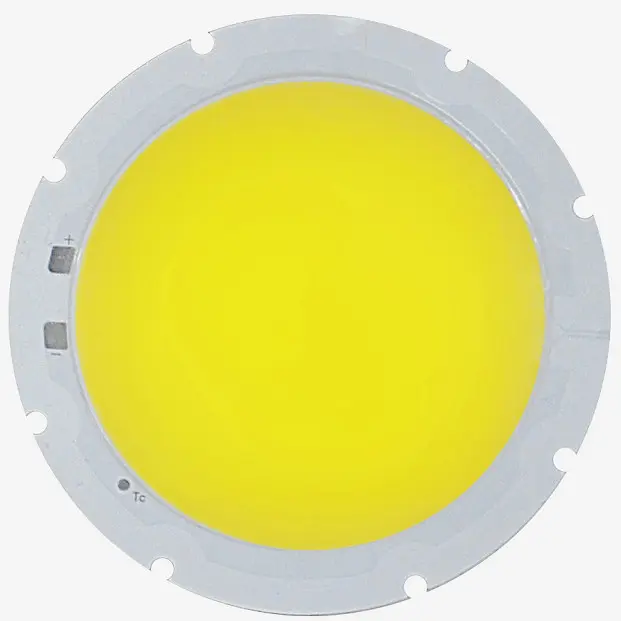

COB: Short for Chip on Board, which means Chip on Board packaging technology. COB can be simply understood as the luminescent body of multiple LED chips integrated and packaged on the same substrate.

COB integrated packaging is a mature LED packaging method. With the wide application of LED products in the field of lighting, COB surface light source has become one of the mainstream products in the packaging industry.

COB light source is a high-light efficiency integrated surface light source technology in which the LED chip is directly attached to the mirror metal substrate with high reflective rate. This technology eliminates the concept of bracket, and there is no electroplating, reflow welding, or SMT process, so the process is reduced by nearly one third and the cost is also saved by one third.

COB light source can be simply understood as a high-power integrated surface light source, and the light area and size of the light source can be designed according to the appearance structure of the product.

Product features:

●Cheap and convenient;

●Electrical stability, circuit design, optical design, thermal design is scientific and reasonable;

●The use of heat sink technology ensures that LED has industry-leading thermal lumen maintenance rate (95%);

●It is convenient for secondary optical matching of products and improves lighting quality ;

●High color, uniform light, no light spot, health and environmental protection;

●Simple installation, easy to use, reduce the difficulty of lamp design, save lamp processing and subsequent maintenance costs.

There are two main forms of raw Chip technology: COB technology and Flip Chip technology. Chip on Board Package (COB), the semiconductor chip is mounted on the printed circuit board, the electrical connection between the chip and the substrate is achieved by the lead suture method, and covered with resin to ensure reliability.

What are its advantages?

In terms of cost, compared with discrete light source devices, COB light source module can save device packaging cost, optical engine module manufacturing cost and secondary light distribution cost in lighting applications. In the lighting system with the same function, the overall cost can be reduced by about 15%. In performance, through the reasonable design and mold making micro lens, COB light source module can effectively avoid the separation of the light source device combination of point guns, glare, etc, can also by adding the appropriate combination of red chips, on the premise of not reduce the efficiency of light and life, effectively improve the color rendering of light source (now can be done more than 90).

In application, COB light source block can make the installation and production of lighting plant more simple and convenient. In terms of production, the existing technology and equipment can fully support the large-scale manufacturing of COB light source module with high yield.

COB planar light source new fourth generation light source, can also be said to be the fourth generation of light source evolution product, because its light source is a chip light-emitting diode. But the difference between the two is the encapsulation technology. The fifth generation light source uses the world’s most advanced high-tech packaging technology, encapsulates the ordinary light-emitting diode in a small area of the plane, so it is called the surface light source. Compared with point source, under the same wattage conditions, surface light source surface area than the point light source surface area of narrow scope biggest reached more than 10 times, thus the heat generated by the corresponding reduced 5 to 10 times, greatly reducing the energy consumption, and because of the heat dissipation problem of light failure problems, and makes lighter, concise assembly lamps and lanterns of the shell. The luminescence Angle and effect of the surface light source are better played and applied under the refraction and concentration of the lens, so that the luminescence Angle can be arbitrarily adjusted, and the secondary light distribution can be formed. Because of the large luminescence area of point light source, the lens is more difficult to use, and the luminescence Angle becomes a dead Angle.

Post time: Jul-22-2022