Table of Content

● What is a COB light source?

2)K-COB Dual Heat Sinking Channel

3)Thermal Resistance data comparison

● Are COB lights better than LED?

● What is the difference between SMD and COB LED?

● Examples of COB Lights

● Concluding Words

1. What is a COB light source?

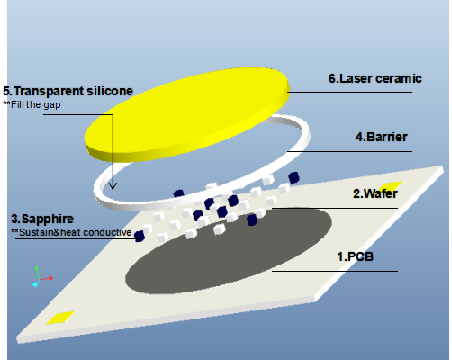

chip on board led lights:we use special laser ceramic(patented)as core packing material, and packaging with our exclusive 3D packaging pattern: using particular sapphire as sustainment&heat conductive path

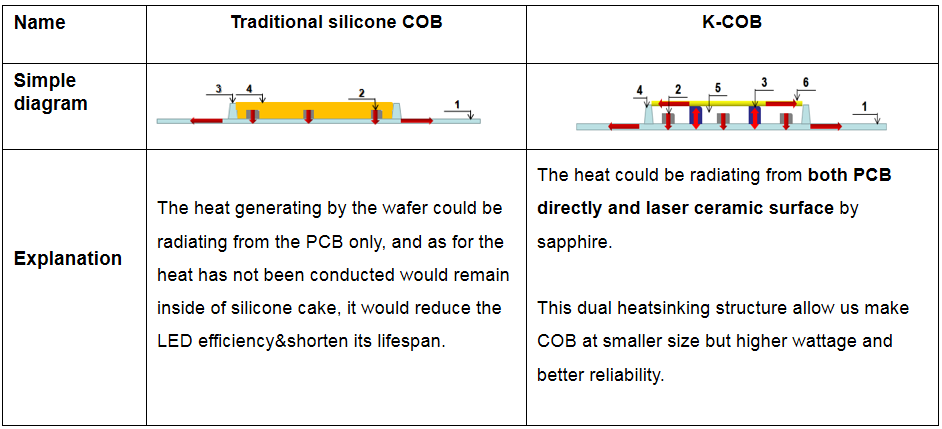

Traditional silicone COB

K-COB

2) K-COB Dual Heat Sinking Channel

The combination of excellent heatsinking performance from laser ceramic and dual-channel heat-leading structure,K-COB resolve the COB heatsinking problem once and for all.

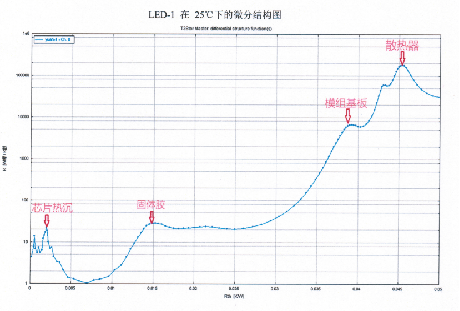

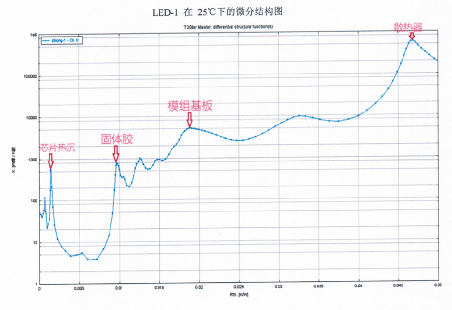

3) Thermal Resistance data comparison

The actual testing data is tested by equipment MicReD® T3Ster, as you can see, K-COB thermal resistance is just 72% of traditional COB.

Traditional COB 500【0.025KW】

K-COB 500W【0.018KW

2.Are COB lights better than LED?

Nowadays, due to the awareness of energy saving and ECO lifestyles, more and more traditional light source such as MHL, HPS has been replaced with LEDs.

LED is a mature technology and has been through a long time since invented, however there are still some types of lighting application that LED hard to do well such as high mast application. This kind of case always requiring of : high reliability, high ground lux level and glare prevention.

Due to the high maintainance expense, the reliability of the lamp is extremely important.

The lamp failure is aways due to: 1. failure of power supply; 2.failure of light source;

While COB achieves high light flux & small size, both wafer and fluorescent materials are facing more TMP challenges. The heat generating from the light source is so centralized that it will Invalidate the LED wafer and fluorescent material (usually silicone) if not taking care of properly. High TMP would lower light efficiency of LED wafer too.

So if we can package LED with a specific materia that has low TMP resistance & good physical properties, the LED chip could have better reliability and longer lifespan

3.What is the difference between SMD and COB LED?

SMD is the abbreviation of Surface Mounted Devices, which is one of SMT (Surface Mount Technology) components. There is only a single chip or a few chips on each light source

COB chips typically have 9 or more diodes. COB chips also only have 1 circuit and 2 contacts, regardless of the number of the diodes. This simple circuit design is the reason for the panel-like appearance of COB LED light (SMD light, on the other hand, appears like a collection of smaller lights).

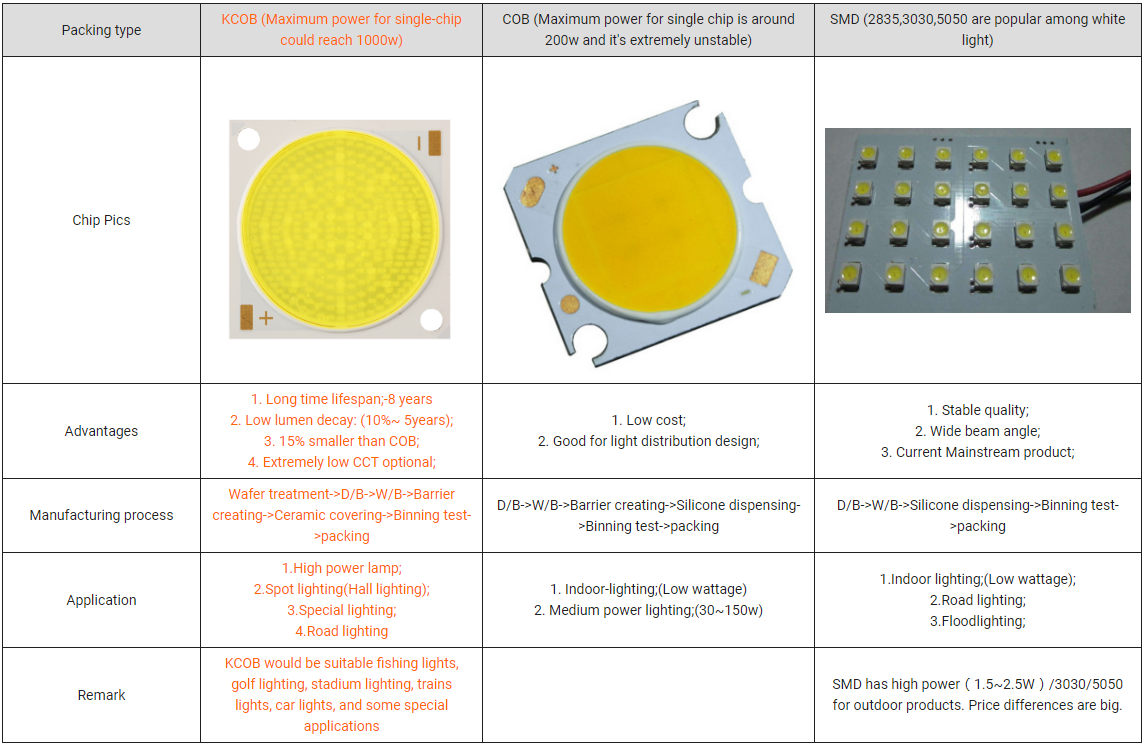

As far, the difference between SMD and COB LED chips is as following:

4.Examples of COB Lights

To choose the best COB light for you, consider luminosity (the output in lumens), versatility (lighting modes), reliability (power supply requirements), and build quality (e.g., waterproof or not). Check out the following examples to get you started.

K-COB SPORTS FIELD LIGHTING SPLC(BASIC SERIES) 600-1200W

SPLC series is a High Power LED Fixture For Sports Lighting. It’s our private mold with Single 1600w Phosphor Ceramic COB, high efficacy reflector, and customized dual heat pipe heatsink, Patent Listed In China, Korea, Japan, And The USA.

SPLC is aimed at big stadium lighting such as golf resorts, soccer fields, basketball stadiums, rugby pitches, baseball courts, etc.

COB LED TUNNEL LIGHT 100W-300W

K-cob tunnel light is designed by a team of professional lighting engineers. This model is a private molding product, and very compact in the outlook. It’s IP65 and impact resistance and durable enough for applications such as tunnels, streetlights, and other outdoor floodlighting applications.

COB MARINE SEARCHLIGHT 300-500W

Marine Searchlights are used and needed for various purposes in maritime industries. They are used for navigation purposes, for example, to identify routes and ship buoys. They also support the search for missing people at sea and allow dangers such as icebergs to be detected at an early stage. A searchlight is a crucial piece of equipment on any commercial vessel that operates at night.

K-COB LED HIGH MAST LIGHT 300W-1000W

High mast lighting is used in large public or commercial spaces such as warehouses, shipyards, rail yards, highways, parking lots, stadiums, etc. They are installed in the fairly tall mast ( 18m to 30m) to illuminate large spaces evenly.

In addition, they are controlled by a motorized drive mechanism, which facilitates the process of installation and maintenance.

5.Concluding Words

① The use of COB LEDs in lighting applications is increasing as user realize the benefits of using them over the traditional standard LED options.

② Flexible usage, compatible with the mainstream lighting accessories in current market Phosphor deposition process can effectively improve the reliability of products.

③ With their ability to pack more LED sources into a smaller space for increased lumen output, their ability to transfer heat more effectively to a heatsink.

④ The lower failure rates due to their simpler construction, their lower light loss, and their increased viewing angle. Ensuring uniform optical performance in general LED lighting applications.

Post time: Nov-25-2022