Cob light source and LED light source which one is better ?

Lamp is very common in our life, with the development of science and technology, there are many new types of lighting. they have many fuctions, and also have many of the types of light sources.CoB light source is the most representative one. Cob light source is a high light efficiency integrated surface light source, which is directly attached to the led chip on the mirror metal substrate with high reflective rate, and has no electroplating, reflow welding and SMT process, so the cost of COB light source is more lower. But there are many friends are not very familiar with the COB light source, so let me tell you about the knowledge of the COB light source.

What is the Cob light source

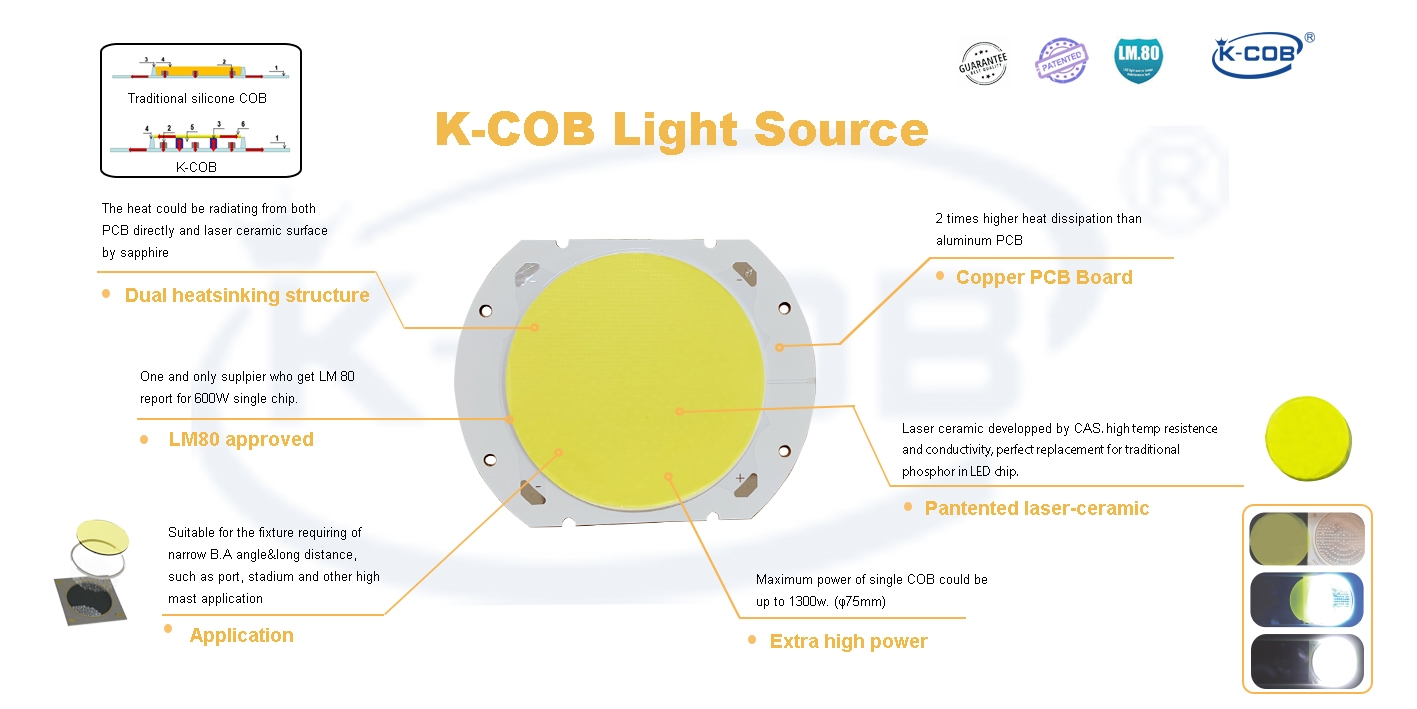

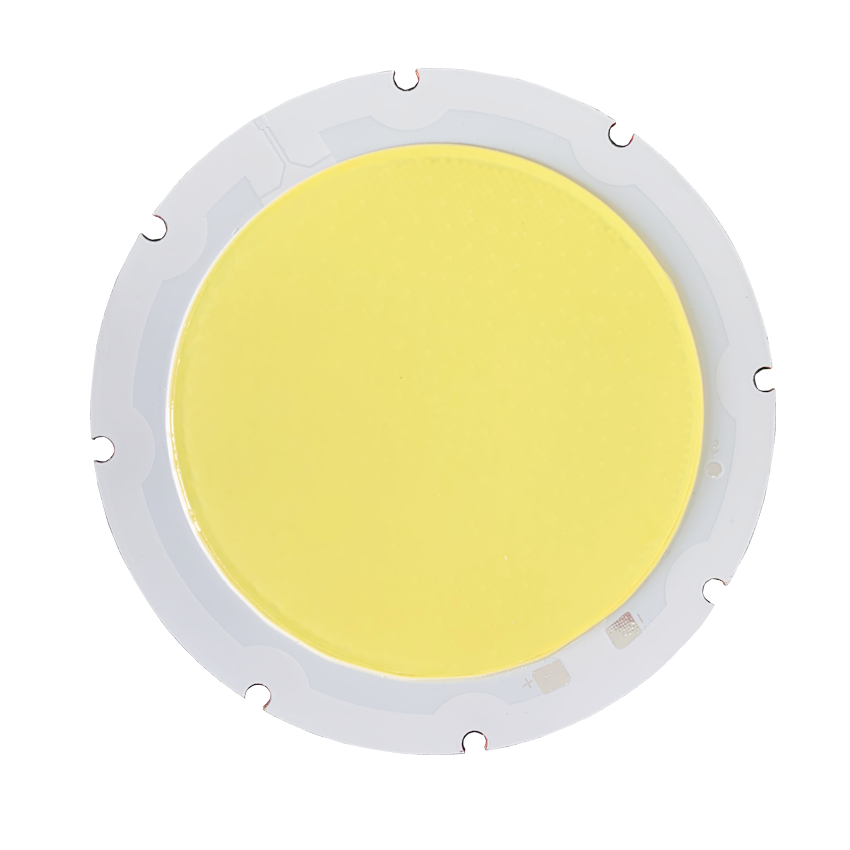

COB light source is a high light efficiency integrated surface light source technology that directly pastes the LED chip on the mirror metal substrate with high reflective rate. This technology eliminates the concept of bracket, and has no electroplating, reflow welding and SMT process. Therefore, the process is reduced by nearly one-third and the cost is also saved by one-third.

Cob light source main products

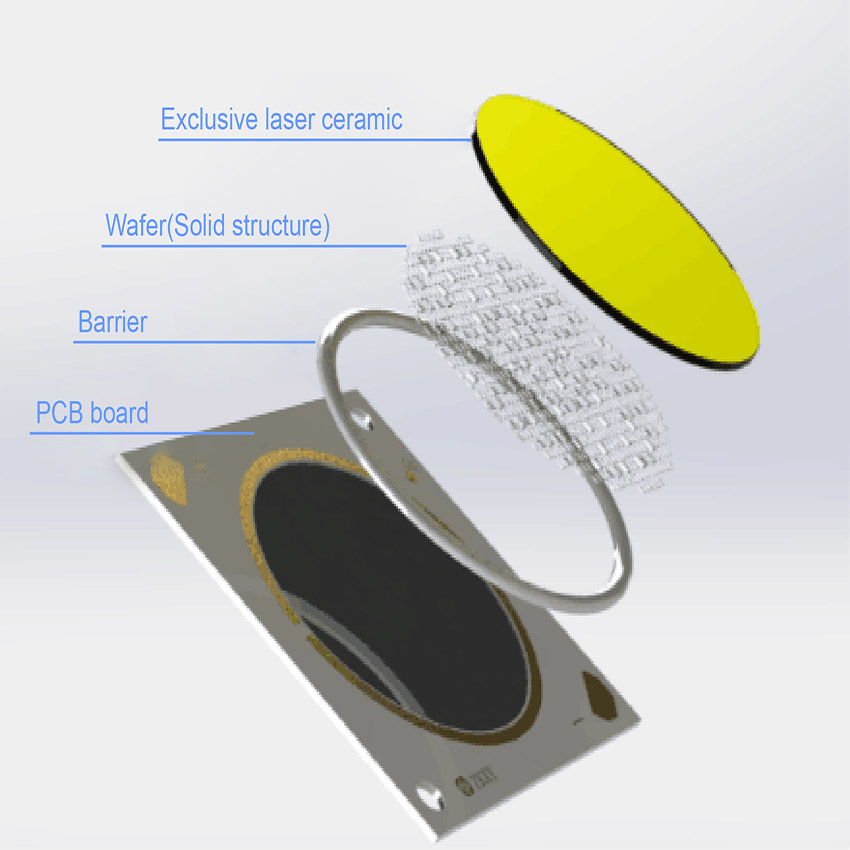

There are two main forms of bare Chip technology: COB technology and Flip Chip technology. Chip on board packaging (COB), semiconductor chip handover affixed to the PRINTED circuit board, chip and substrate electrical connection is realized by lead suture method, and covered with resin to ensure reliability.

Cob light source production process

The process of Chip On Board (COB) is to cover the silicon wafer placement point with thermally conductive epoxy resin (generally silver doped epoxy resin) On the surface of the substrate, and then place the silicon wafer directly On the surface of the substrate, heat treatment until the silicon wafer is firmly fixed On the substrate. Then wire welding is used to establish a direct electrical connection between the silicon wafer and the substrate.

Cob light source and LED light source which one is better ?

Traditional LED: "LED light source discrete device →MCPCB light source module →LED lamps", mainly because there is no suitable core light source components, not only time-consuming, but also high cost.

Package "COB light source module →LED lamp", can directly package multiple chips on metal base printed circuit board MCPCB, through the substrate direct heat dissipation, save LED packaging cost, optical engine module production cost and secondary light distribution cost. In terms of performance, the COB light source module can effectively avoid the drawbacks such as spot light and glare existing in the combination of discrete light source devices through reasonable design and microlens molding. The color rendering of the light source can be improved effectively by adding the appropriate combination of red chips without significantly reducing the efficiency and life of the light source.

The relative advantages are:

Manufacturing efficiency advantage

The production process of packaging is basically the same as that of traditional SMD production process. The efficiency of PACKAGING is basically the same as that of SMD in the process of solid crystal and welding line. However, the efficiency of COB packaging is much higher than that of SMD products in the aspects of dispensing, separation, splitting and packaging. COB packaging labor and manufacturing costs account for about 10% of the material cost, using COB packaging, labor and manufacturing costs can save 5%.

The light source

Traditional SMD packaging uses the form of patches to attach multiple discrete components to PCB boards to form light source components for LED applications. This approach has problems of spot light, glare and glow-out. K-COB package is an integrated package, which is a surface light source, with a large Angle of view and easy adjustment, reducing the loss of light refraction.The color rendering of the light source can be improved effectively by adding the appropriate combination of red chips without significantly reducing the efficiency and life of the light source.

The above is to share with you the basic knowledge of COB light source, I hope you can better understand the COB light source through our sharing. K-cob light source,which developed and produced by our company - SFUJIAN CAS-CERAMICS OPTOELECTRONICS Co.,Ltd .

K-COB can be simply understood as high power integrated surface light source, and its biggest characteristic is low cost, easy to use, heat dissipation and luminous are very scientific, so K-COB light source is more and more recognized by everyone. And now most of the light source used for lighting is COB light source, which not only has good lighting effect, but also saves energy.

Post time: Mar-29-2022