What are the parts of the light fixtures?

1.led light source

2. Circuit board

3. Heat sink

4. Driver(Inventronics,Meanwell,Mosopower,Sosen)

5. Thermal grease (used for bonding heat conduction between lamp beads and circuit boards and between circuit boards and heat sinks)

6. Secondary light distribution materials

7. Lamp housing

Today we want to introduce LED LIGHT SOURCE for you at first.

1.Why chose led light source?

Nowadays, due to the awareness of energy saving and ECO lifestyles, more and more traditional light source such as MHL, HPS has been replaced with LEDs.

LED is a mature technology and has been through a long time since invented, however there are still some types of lighting application that LED hard to do well such as high mast application. This kind of case always requiring of : high reliability, high ground lux level and glare prevention.

2.What is advantage of COB?

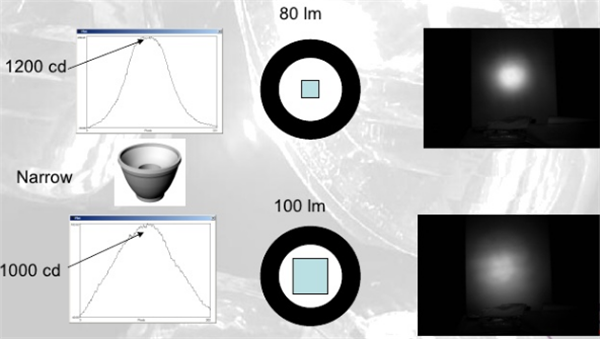

While COB achieves high light flux & small size, both wafer and fluorescent materials are facing more TMP challenges. The heat generating from the light source is so centralized that it will Invalidate the LED wafer and fluorescent material (usually silicone) if not taking care of properly. High TMP would lower light efficiency of LED wafer too.

So if we can package LED with a specific materia that has low TMP resistance & good physical properties, the LED chip could have better reliability and longer lifespan.

3.What is advantage of Laser-ceramic:

1)One of the main advantages for the laser ceramic is high heat conductivity rate: 13.367W/m.k, 75 times of traditional phosphorous powder (YAG05+sil1018).

2)Small lattice spacing and near single molecule structure will bring less lumen loss and higher reliability;

3)Hard surface, impact proof and also good resistance for temperature& acidity and alkalinity change.

What is advantage of Laser-ceramic

4.How to protect light source?

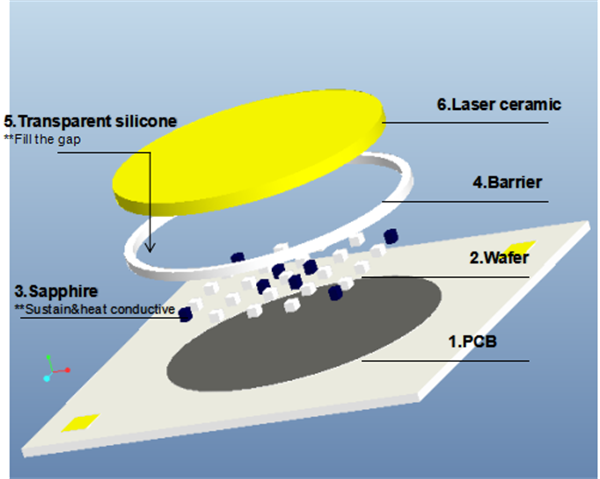

We invent phosphor ceramic COB-unique led packaging, by using exclusive laser ceramic to replace traditional silicon and phosphor.

K-COB

1)We separate two main heat source of LED chip and phosphor by dual heatsink channel design. This design help to reduce chip junction temperature effectively.

2)K-COB is the one and only COB supplier who get LM80 certificated for single 600w chip

3)The combination of excellent heatsinking performance from laser ceramic and dual-channel heat-leading structure,K-COB resolve the COB heatsinking problem once and for all.

4)Our HB lamp 150W(with KCOB heatsink modular)has been lighting continuously for 1364 days(32,735 hrs) till now, the ground lux stays at 4,000lx, 0% light decay.

Post time: Apr-07-2022